The production of a top quality MDF panel involves high manufacturing costs. The IMAL-PAL group supplies plants and plant areas that have been specifically designed to radically cut production costs, from electrical power, to resins and chemical additives.

Innovative resination and pressing technologies have been applied to the latest MDF plants to reduce resin addition rates and increase production capacity, allowing manufacturers to benefit from a rapid payback and smaller investments, without the need to produce large volumes of MDF panels.

- The wood products industry is considered to have a major role in raising the national income and the local and external economy, as the global consumption of furniture and wood products is constantly increasing, and it is expected to reach $ 654.8 billion by 2026.

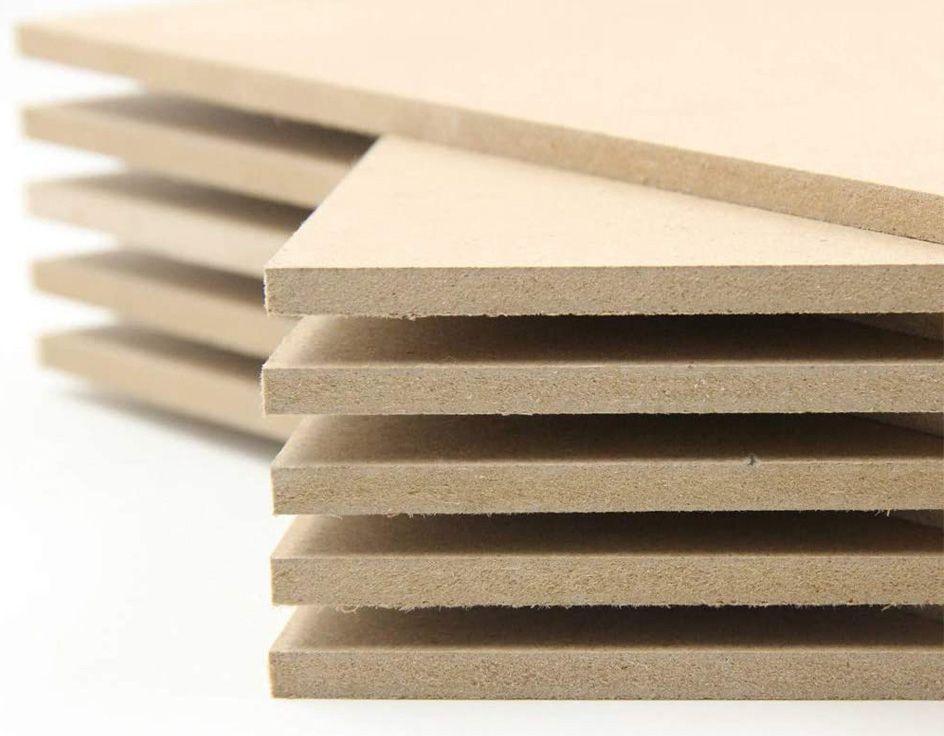

- Wood panels and veneer chips are one of the raw materials that are widely used in carpentry and decoration works due to their different types and features.

- Fiber wood or wood pressures are medium-density sheets that are manufactured from wood fibers through heat, drying and pressure, with the addition of some auxiliary stiffeners, and then straightening the board under the influence of heat in the form of plates of different thicknesses.

- MDF is considered one of the most common types of wood panels due to its strength and softness on both sides, as it is ideal for paints and veneer paste.

- The production of a top quality MDF panel involves high manufacturing costs.

- The IMAL-PAL group supplies plants and plant areas that have been specifically designed to radically cut production costs, from electrical power, to resins and chemical additives.

- Innovative resination and pressing technologies have been applied to the latest MDF plants to reduce resin addition rates and increase production capacity, allowing manufacturers to benefit from a rapid payback and smaller investments, without the need to produce large volumes of MDF panels.